Stuart Elsy, managing director of OSO Hotwater considers what should installers be looking out for to ensure they are recommending an effective system?

Most people would agree that you get what you pay for in this world. In the boiler industry, the boilers with the strongest sales are generally those with strong emphasis on quality and efficiency, often coupled with a strong brand name that is recognised by the public who are willing to pay good money for a good boiler. This is not always the case in other areas of the heating industry. Many installers will perceive a hot water cylinder as a commodity box that does the same job as another commodity box. This is a long way from the truth, and there are many variations in quality, efficiency and innovation.

OSO has always been more expensive than other brands. With a Norwegian base, this was never going to be anything else, but OSO has not only survived, but thrived on being innovators at the cutting edge of technology, quality and efficiency.

Efficiency is all important in the design of water heaters. Fuel efficiency and space efficiency.

Put simply, the best way of establishing the energy efficiency of a water heater is to look at the ErP energy label. The figures don’t lie, particularly if they are independently approved by the Hot Water Association Charter audit.

Indirect cylinders

When selecting a cylinder on efficiency, do not just look at insulation thickness. It tells only half the story. Better quality insulation is far more important, and this is shown in the ERP rating.

Indirect cylinders are measured on standing heat loss. This test heats the water to 65°C with a surrounding temperature of 20°C, and then measures the energy required over 24 hours to keep it there. ErP has radically improved the general standard of insulation. Poor performing cylinders below a C rating are now illegal, but there are still significant differences in performance.

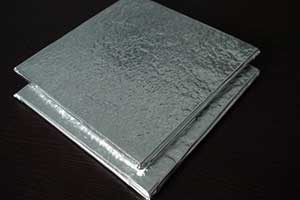

The very best performing cylinders use vacuum panel insulation. Heat cannot travel through a vacuum and a 10mm vacuum panel has the same insulation properties as 60mm of PU foam. The OSO Delta has a 10mm vacuum panel, backed up with 40mm of foam and is comfortably the best insulated product available – the only full range of A-rated cylinders on the market. A 300 litre Delta loses only 3.5°C in 24 hours, an equivalent older cylinder from circa 2000 lost 13°C. This efficiency gain alone can save customers up to £78 per year on their heating bills.

Central heating system efficiency

Central heating system efficiency

Highly insulated cylinders, in reality, don’t need to go in an airing cupboard, increasing installation flexibility. In fact, the best cylinders can easily be fitted in a loft or garage. The small amount of additional heat loss that will occur because the ambient temperature is lower in those environments will be a small cost, when compared to the addition space created by removal of the cylinder from the first floor.

With this in mind, installers should think very carefully before suggesting the removal an old cylinder and replacing with a combi boiler. Cylinders have a fundamental advantage in houses with more than one shower/bathroom in that they are able to supply two or more showers simultaneously. Recent research conducted by the Hot Water Association, revealed that almost a quarter of families argue regularly about who is going in the shower first. This doesn’t have to happen with a cylinder.

To maintain central heating efficiency, it is very important to ensure that the interface of pipework between boiler and cylinder is correctly lagged and that modern heating controls are used.

Heating costs in indirect cylinders can also be affected by hard water. Opting for a coil which is smooth will attract and harbour far less limescale than a ribbed or finned coil, cutting the effect of Limescale acting as insulation between primary and secondary water. Building regulations Part L recommends that hard water is treated to reduce calcium and preserve the efficiency of the system.

In the worst cases, cylinders can just fill up with limescale, and because the South-East and East of England in particular are known hard water areas, the design of a heat-exchanger in a cylinder should always be a factor to consider for installers in those areas. OSO only use smooth skin coils to limit this effect.

Direct cylinders

Direct cylinders are tested on energy input compared to heat output. It’s quite a complicated test, and shares roots with the hot water test for combi boilers. Standing heat loss plays a part in the test efficiency, but many of the best cylinders are now those with smart control via a self-learning thermostat.

Smart control matches heat input to predicted hot water demand and can save 30% in terms of energy input over standard on-off thermostats. The newly launched OSO Super SX iQ range of cylinders has been shortlisted for multiple industry awards and utilises smart control to save customers significant electricity costs over a year.

Space Efficiency

Efficiency is not always just about energy efficiency. Space efficiency can be equally important to a householder. Back in the mists of time (1989), OSO invented the bubble top system. Many other manufacturers “borrowed” it during the 1990s, some more successfully than others. OSO dropped the bubble top unit some time ago to replace it with an improved design on the Super Series that has all the space saving advantages of the bubble unit, but which dispenses with the annual bubble replenishment procedure normally recommended as part of a service. The Super Series design is now a patented design.

Cylinders with separate expansion vessels do the job but take up a lot of space. Bubble top units are more space efficient, but the all-on-top design of the Super Series with twin mini-expansion vessels concealed under a lid, are guaranteed not to lose their charge for at least 5 years and gives a space saving and maintenance friendly alternative.

The space saving features of Super Series are accentuated with the SX IQ because it heats and stores water at 70°C; 10°C higher than most other units. The cylinder contains a blending valve in its multifunction valve and blends the water to 60°C at the outlet, thus eliminating any risk of scalding. This extra energy storage means that a smaller cylinder can be specified, saving further space and in practical terms means that a washing machine can be stored underneath the cylinder up to 210 litres in a standard airing cupboard. No other product has that flexibility.

The simple answer is no, not all hot water cylinders are the same. Efficiency, quality and technological advances differ and it is certainly worth taking a look to make sure the heating system will deliver but also exceed expectations.

Add new comment